Roof Wind Uplift Screen Wall

When building a structure it is important to calculate wind load to ensure that the structure can withstand high winds especially if the building is located in an area known for inclement weather.

Roof wind uplift screen wall. Panel width and profile metal type and thickness clip type and frequency type and number of fasteners and the roof deck contribute to the uplift resistance of every metal panel roof system. The highest roof pressures often occur along the roof eave overhangs and corners of the roof see figure 1 and 2. The second phase of the study focuses on the wind loads on the screen walls themselves. Wind uplift damage to older buildings.

The roof screen sections are designed to handle approximately 100 mph winds 30 lbs. Metal panel roof systems installed over solid substrates with concealed clips or through fastened can be designed using the following test standards. Also the screen type does not significantly change wind loads on the equipment being screened. To ensure a correctly built metal roof there are a variety of wind uplift tests manufacturers use to test their metal panel systems.

It focused on the effects of rooftop screens on the wind loads applied to the equipment being screened. Wind uplift occurs when air pressure below a roofing system is higher than that which is above it. Roof design wind loads are the wind pressures and resulting uplift forces for which the roof structure is designed. Many studies on roofed structures have been performed in the past.

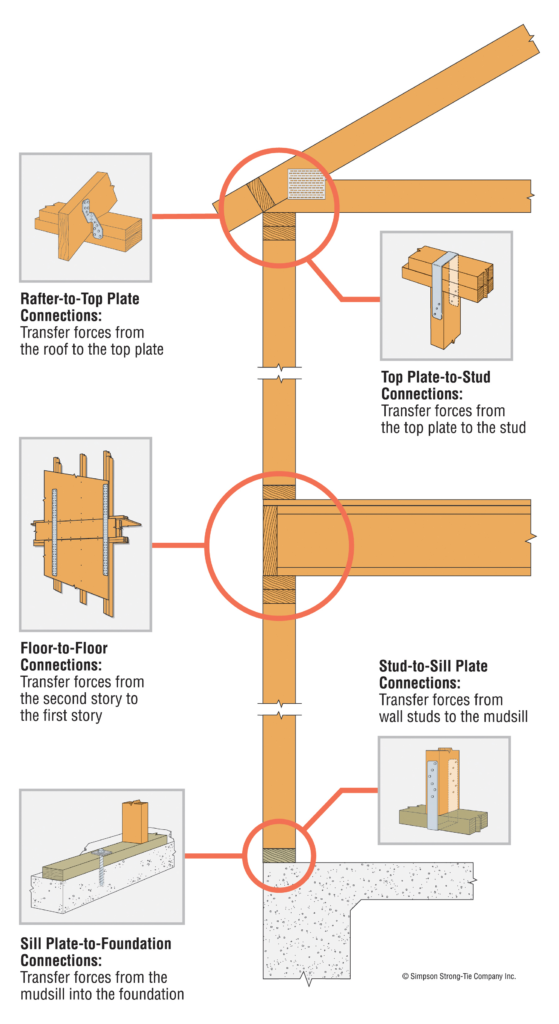

Preliminary findings suggest that fully enclosed screen wall configurations do lower wind loads on the equipment while partially enclosed screen configurations do not provide significant wind load reduction. In order for a structure to be sound and secure the foundation roof and walls must be strong and wind resistant. Asce 7 10 requires uplift forces of 1 5x the lateral wind pressure applied as an uplift force on rooftop structures for buildings less than 60 ft but does not require the uplift for rooftop structures on buildings greater than 60 ft. This includes structural components such as roof sheathing or rafters or roof cover components and the connections of these elements.

What is wind uplift. 1 3 3 roof design wind loads. These tests are necessary to understand how a metal roof system can withstand both external and internal pressures which is important when trying to meet design and performance requirements in projects. Design and performance requirements there are three tests ul 580 ul 1897 and astm e1592 that are used to determine a metal roof s uplift rating.

The present study demonstrates the pressure variations due to wind load on the pyramidal roof of a square plan low rise building with 15 wall openings through cfd computational fluid dynamics simulation. This seems like an arbitrary cutoff. Roof shape and slope are both important parameters for the safety of a structure especially when facing wind loads. Like an airplane wing upon take off this effect draws the roofing panel upwards possibly damaging or tearing the roof.

There are a number of factors that go into creating wind uplift from roof slopes to wind gusts. For older buildings without uplift connections when they sustain damage due to high wind events we often observe detachment of the roof framing from wall top plates due to wind uplift. As wind passes over the roof the pressure above the roofing system drops while the pressure below is increased through holes and entry points.